I was planning on going out for a beer tonight. I am in the city on a rare Friday night and here it is, St. Patricks Day. I had really thought about going out for a beer. But it is about six block walk from the shop to the bus. It is windy and cold and damp. Going, the wind would be mostly behind me. But coming back, well, I know I would need at least three pints to make that walk into the wind and I have more conference to attend tomorrow. No, I just couldn’t do it. I would never drive there and drive back. I don’t hold my liquor that well any more. …Out of practice. With no heat the van isn’t quite setup to drive there and sleep over in the neighborhood. Getting very close though.

In fact I suppose I could have even been there. I think I have all the parts purchased for the furnace hookup. But I really wanted to work on something else.

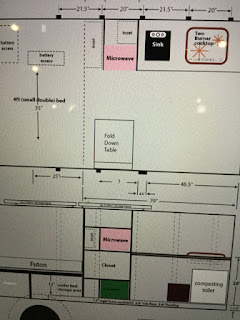

Beside the bed the plan is to have a shelf/closet that goes from the floor all the way up to the ceiling. …Uh, well not that there is all that much “all the way”, …but you know what I mean. This will be home to the microwave I purchased earlier tonight. It might also house the refrigerator —if I can afford it and this continues to seem to be the best spot. We are entering the phase of the project where the infrastructure is starting to come together. The things that have to be in one particular spot for some reason are getting placed there. Now it is a matter of doing some active design. Where I have a pretty good idea of the rest of the things we need, the question is now, where should these items really sit? Is the best spot for a refrigerator really in the base of this? Or, would a better spot be more in the kitchen next to the furnace? I think decisions like that are impossible to form yet.

|

| Calling the bottom edge square, the paper sticks out beyond the cardboard by about ten inches. This will be the profile edge. |

What I am going to try doing is something I have read about. I can do some cardboard mockups of the refrigerator and move it into various spots. I don’t have the money for it anyway. I have refrigerator dreams on a cooler budget. So it isn’t really a matter of slowing down the project by having a box in here that is labelled refrigerator. In the meantime maybe I will discover I can survive on the cooler, maybe I will decide I can’t live without using that 2.7 cubic feet for something else.

So folks, it’s back to the shop and it was a great night to work on the van.

Tonight what I did was cut out the side walls of the floor to ceiling shelf. I had thought some of hooking up the furnace. But, I will be quite honest with you, I have ulterior motive for working on the shelf instead. With this wall in place while I am laying in bed it blocks the light from the red exit sign here in the shop from hitting me right in the eyes. I have really been looking forward to this night’s sleep.

To install the shelf I needed to produce a profile of the van cut in 3/4” plywood. I started with a hunk of stiff cardboard, like from a heavy box. The cardboard stiffness was more important in this case than it has been for the prior templates I have cut. Because it was standing up and I wanted it to stay square with the floor, the stiffer board helped that. That cardboard was maybe a little less than two feet wide. It was about six inches less than the height of the van. Next I used another sheet of my fish poster paper. You could use any sort of fairly stiff paper I suppose card stock or construction paper would be perfect as well. I took one poster and cut it in half the long way. This gave me two long strips. Tape them onto the cardboard with about ten inches hanging off the edge of the top and one side. This will be your profiling edge. I lined the cardboard up with the edge of my bed. Then it was just a matter of trimming the paper and sliding the cardboard edge closer to the outer wall. At first you can cut off some fairly major hunks but as you go, take off smaller and smaller nibbles.

|

| Ready to start cutting. |

I am building with the thought I want to be accurate within half an inch, but a lot closer in a couple of key areas. It is my thought this van has a fair amount of body flex. So given this, I think I want to have only a few really solid mount points. The side next to the bed will mount firmly to the edge of it. On the frame corner, where the ceiling meets the wall, I will screw wooden blocks into the frame and then glue and screw them to the shelf wall. Basically the way I look at this as, I am going to attach my shelf everywhere the ribs are attached, which is the top and the bottom. I think the skin of this van needs to be able to shift around a bit. I don’t want it touching the outer skin anywhere. I think that is how you make squeaks.

After the profile is all cut to fit, lay it over a sheet of plywood. Here is a place I made a little error. But, though I did what I did by mistake, I don’t think I have wanted to do it the right way. The short version of this is my cooktop requires a 24” counter top. So thinking in terms of my shelf walls, I thought, hey this is great because I need two and a sheet of plywood is 48” wide. The trouble with this logic was my shelf goes (almost) all the way to the outer skin, attaching to the struts. But the counter has to be 24” from the surface of the interior wall covering I have yet to build. My shelf ended up being about two inches narrower than that. So it was an error for me to cut it this way, but in the end, I am not sure I would have done it any different. To have done it right would have taken the purchase of a second sheet of plywood, an extra $50 for two inches. This will commit me to some sort of solid surface countertop material. Corien, or the like, because the end of the counter with the cooktop has to be 24, the shelf end only 22.

Tonight though I laid my template over the plywood and traced it out. I used the bottom edge of the cardboard and lined that edge up with the end of the plywood. I put the curved, paper cutout side of the template toward the center of the sheet. When I got one traced out, I flipped it over and traced out the second upright, again with the paper side of the pattern facing in to the middle of the sheet. When I was done I had the two sides of my floor to ceiling shelf drawn out on the plywood.

|

| Mmmmm, the smell of new power tools! |

I might have mentioned in a previous installment my Craftsman jigsaw gave up the ghost. I didn’t remember having a problem with it the last time I used it, but on this project it had no power at all. It would cut, very slowly if I didn’t push it too much or turn any corner that might bind the blade even a little bit. In those situations it would just stop. I had to pull back to give the blade a little room and then it would start cutting again. Very sad. This saw and I have been through a lot of projects together! Tonight since I ended up buying a microwave sixty dollars cheaper than the original one I had picked out, I figured I had a little extra money. I bought a brand new Dewalt jigsaw. Sort of a middle of the range saw, but wow! I couldn’t believe how well it cut. I am not sure my trusty Craftsman did as good even when it was brand new. …And it hasn’t been brand new for at least 30 years. It cut through that 3/4” plywood like butter.

|

| An opening for the gas pipe and electrical wire going to the furnace, lights and toilet vent fan. This list might grow so I oversized it. |

Once the basic uprights were cut out I brought them into the van and marked a couple of things. The differences between the two. For instance, the back upright had to have a cutout for the wheel well. The front one needed a hole for the gas pipe and electrical runs to pass through. Additionally, I had cut the front one just a little taller than the back one. There seems to be a little bit of height difference between the two areas. Maybe a quarter of an inch. Could it be the frame sags down a little? I had left it just a it longer than I should have so I had to trim it just a little bit to get a perfect fit.

When I was done, I had the two uprights in place just to get a sense of the space. It was really interesting, since I have been looking at this van as open space for almost three months now. Suddenly it has this wall in it. Really different. I am almost positive when The Wife is on board we will sleep with our heads at the other end. It is a claustrophobia issue for her and it is possible she will think this wall too enclosing. And yet there is the privacy issue. We are both intensely private people when it comes to bathroom usage, even after 25 years. We think it is crazy there are open door bathroom couples. So this is very out of character for to have toilet use in the room we are both in. With our heads at the wall end the view to the toilet will be blocked. I will just have to see how that plays out.

Of course I had a little diversionary project I tried to do as well. In order to manage my ADHD I tend to putter a little on this and a little on that. I look at it like this van project list as not all that long but it is about a mile wide. I move it along an inch at a time. This side project jumped the tracks pretty quick though.

Being St Patrick’s day, I have to wonder if I don’t already have an infestation of the ‘wee folk before I even have the thing built! I mentioned previously my saga with losing the ANL fuses. I had them. They were in my hand at one point. So I know I received them from Amazon. But that was the last I saw them and I spent about a week of spare time digging through the shop, the van, my cubical and my home. No fuses. I gave up. Ordered more but won’t have them for two weeks.

|

| Digging through the electrical bag to find the auto fuses. |

Ok so tonight I decided to install this cool little LED gas gauge that reads the battery charge. I am sure it is wildly inaccurate, but it sure looks cool! I installed on the panel just inside the back door. It might stay there or I might install it where I can see it in bed. I will have to see how bright it is. I had to bore out the mounting holes a little bit to accept some #6 black cap screws. Then I mounted it onto the panel. The 12v circuit panel was right there and good practice dictates this meter be fused. I have plenty of spots so wired it into the #12 spot on the fuse panel. Done. Ready to test. Two weeks ago I purchased not one but two boxes of “Misc Small Auto Fuses”. These like you used to have in your cars until about ten years ago. The little variously colored plastic fuses with wide metal legs. I was figuring to have enough fuses for the life of this van by having two boxes.

Well I spent a good thirty minutes digging through everything to find those boxes of fuses. Never found them. Damn.

No comments:

Post a Comment